Ethically Sourced Products

Sustainability is not just about reduce, reuse and recycle. Most people seem to think that by upcycling or recycling waste, that we are reducing the impact on the environment. While this is true, it is also important to think about the inhabitants of the planet. What about those crafts people who make things by hand in the face of industrialization? By this I mean the peoples from disadvantaged societies across the globe. They have to compete with industrially finished goods to attract patronage of their craft.

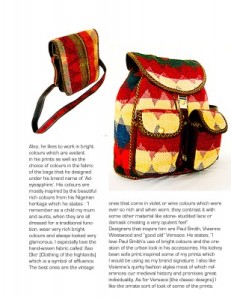

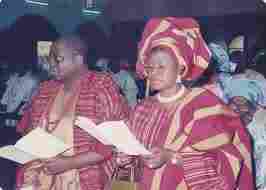

For instance, fashion and textile designers tend to overlook the cloth weavers in other cultures who have an immense portfolio of work that are used in their indigenous traditional fashions. A lot of them are very good quality fabrics that reference their native designs which are consumed locally. A good example of these are the Aso-Oke weavers from Western Nigeria, the Kente fabric makers of Ghana and even the Jajim carpet cloth and weavers of Persia and the middle East.

Fig 1. A Nigerian lady in traditional Aso-oke attire. Courtesy: www.googleimages.com/12:10:2012

Fig 2. This is how Aso-Oke is worn for very important Nigerian occasions like weddings. Its a symbol of affluence. – Pictures courtesy: www.GoogleImages.com/12:10:2012

Here in the UK and other parts of the Western world, people only ever see these textiles as traditional Nigerian garb and nothing else. The material is only consumed by the natives at home and abroad so the market is very limited to these people.

My case for the likes of these is that they can be utilised in our everyday fashion and accessories consumption not only because they were made by hand, but because they are a very durable, colourful textile material that’s yet to be explored by designers in the West as a source material that can be used in fashion and accessories with a modern, contemporary feel.

Fig 3. A pair of slip-ons made from Aso-Oke. – Courtesy: www.triplekstores.com/ google.co.uk

Fig 4. A small handbag. Courtesy: www.google.co.uk

Some of the Nigerian designers have been ingeniously creative by thinking outside the box and creating new uses for these textiles other than what they have been known to be used for traditionally.

In my view, we cannot consider ourselves as ethical enough if we don’t adopt an inclusive approach to design by looking at what the crafts people from other societies are creating in their cottage industries and afford them a good living by using their products when we design fashion garments and accessories.

Recent trends have witnessed bags being made from African wax prints, giving users the pseudo sense that they are subscribing to African traditional designs because they are carrying handbags and hold-alls made from these Dutch products. The wax prints were originally made by the Dutch for the African market and were very popular then as they are now among the African societies. Let’s not be fooled by the fact that while there are a proliferation of textile factories in Nigeria and other parts of Africa that make wax prints, there is nothing indigenous about them because they are still machine processed and further impacting on the environment by polluting it and also taking the livelihood from these crafts people.

When I used to live in Nigeria, I had witnessed textile dyes and chemicals being released into the environment with people being exposed to it. All the drains around the factories were replete with coloured textile waste chemicals from the processes used to make these wax prints and giving off steam and fumes from the gutters. Nobody seemed to bat an eyelid because they did not know of the impact to themselves. And yet, the indigenous cloth makers still had to compete with the industrially mechanised processes of cloth making, thereby making it not-so-economically viable to continue with their trade.

Consumers in these parts need to be made more aware of the dangers that these manufacturing plants constitute to themselves as well as their environment – how it also impacts on the cottage industries – because they are buying into industrial gunk! In the same vein, designers should explore the use of products from these societies by utilising them in their work.

Fig 5. Swashes of African Wax prints. – Courtesy: www.google.co.uk

While the wax prints are beautiful and come in very fetching colours, they do not last that long and tend to lose their lustre after a few washes. Yet, there are the indigenous hand-woven textiles that are just as beautiful and durable as well as versatile that continues to be ignored by fashion designers across the globe. Could this be because everybody jumps on the same bandwagon of using industrially finished textiles for their creations or simply that no one promotes the products of these cottage industries? The answer is in the affirmative.

In addition, Dutch wax prints are still a legacy of the colonial hegemony that seeks to suppress the cultural heritage of the peoples of these disadvantaged societies. Little wonder that the indigenous textiles of such societies are not well known by the outside world and there continues to be a lack of economic equilibrium of these communities who have to fight tooth and nail to get their products to the attention of a world audience.

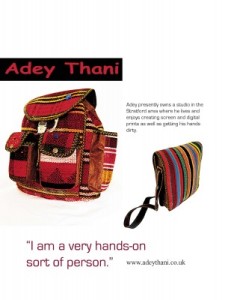

With this background in mind, I have sought to promote these indigenous textiles not only from Nigeria, but from other cultures as well. I started my own brand of ethical products called ‘Adeysapphire Ethical Products’ using Jajim from Persia and Aso-Oke (Nigeria) to make fashion accessories of a variety of bags and wallets in the hope that lovers of these fashion accessories will buy into this idea for the long-term rather than as a fad.

Fig 6. The Adeysapphire label.

Fig 7. An Adeysapphire duffel bag for women designed by Adey Thani.

Fig 8. A messenger bag designed by Adey Thani for the brand.

Fig 9. One of the range of rucksacks for the brand.

These bags were outsourced to a factory abroad after I had researched having them made in the UK and found that it was going to be an expensive venture. Having contacted The little leather workshop in Dalston, I was told it will cost me £35.00 an hour to make the first sample of bags, I was disappointed but not discouraged and continued looking for a way to make my bags as cheaply as possible. Then in the summer of 2012, during the Olympics, I decided to make some hand-printed tote bags which I promoted through social networking sites; twitter and facebook via my website www.adeythani.co.uk.

In the course of approaching retailers to stock my tote bags, I soon discovered that even though I tried to keep my costs down by printing them myself, the cost was still too high to enable them to stock the products. The proprietor of ‘Source’ in Spitalfields market then told me: ” The bags are beautiful and well done, but the problem with you designers fresh from university is that you don’t look at your costs. (Pointing to similar products in her display) That bag was sourced from India and came at a cost of less than £2.00. I sell them for £7.75 and the other one I sell for £10.00. If I took your bags now, how much do I want to sell them for to make a profit? I will have to sell for £20.00 and therefore, it will not compete favourably with the ones from India and China.”

This was the same everywhere I went. I was crushed and felt sad that while I wanted to make my products and sell in the UK, it was looking like it wasn’t such a good idea afterall. It became clear that i would have to outsource them if I wanted to be able to compete. So, I had to settle for selling directly to people on my website and also through selling to individuals. I contacted the buying department of Topshop and never got a reply from them.

As a result, I started selling them at the ‘Electric ballroom’ in Camden with the help of my friend, Kevin who happens to be the manager of the Nightclub-cum-weekend market, where they are still selling today. I also sold some at wholesale to a store on Charing cross road in London.

Fig 10. A hand-printed tote bag featuring ‘London bridge buskers’

Fig 11. A design heralding the Olympics in Stratford 2012.

Fig 12. ‘The queen of chavs’ a humourous design commemorating the Queen’s diamond Jubilee inspired by the Wax work at madame Tussauds in London.

This venture was the beginning of my advent into bags as a fashion accessory. I wanted to stay true to my ethical beliefs and was very inspired when my friend and neighbour who is Iranian showed me some textiles from Iran, I was so impressed that such good quality fabrics can be made by hand and wondered why designers don’t use them in fashion. The fabrics also reminded me of the hand-woven Aso-Oke that are made in Nigeria and the Kente made in Ghana. I marvelled at how smug we all are wrapped up in our technology and industrially finished goods forgetting that there are skilled craftsmen and women in developing economies who can do with a bit of help in promoting their products if designers in the West use them in their contemporary creations. By so doing, we would help the world go round by giving them a fair living wage and encourage prosperity in their local communities and reducing the economic inequality that is a stark reality across the globe today.

I proceeded to designing some bags primarily to sell and finance my Masters studies and also as a way of showing that these ethnic textiles have other uses other than what they are traditionally used for. The bags had an unprecedented popularity because they were so unique and full of bright colours that I instantly thought of creating them as a bohemian street style of bags that would appeal to both the trendy, young and older consumer who wanted to look cool and not averse to the idea of being ethical at the same time.

Fig 13. A swash of handwoven fabric called Jajim introduced to me by a friend.

Fig 14. Another Jajim swash. Courtesy: www.google.co.uk

Fig 15. Ethnic design made in Persia.

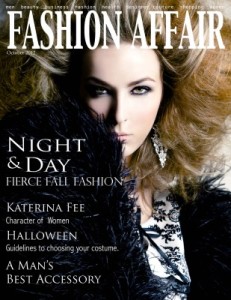

Again, I contacted Topshop, H&M, Urban Outfitters and some other stores, but they were not interested. Then, I was approached by the PR and Fashion editor of Fashion Affair magazine who loved the bags and wanted to feature them in the October issue of Fashion Affair magazine. This publicity helped to drum up traffic to my website because it was the first online magazine where readers could access the designers website.

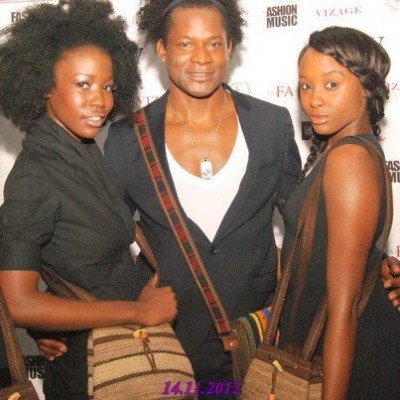

Subsequently, I was invited to take part in a fashion event by a Los Angeles based fashion show organiser who were staging their first show in London called ‘Fashion meets music’ which took place at ‘Cargo’ in Shoreditch on the 14th of November 2012.

Fig 16. A flyer of the fashion event Fashion meets Music.

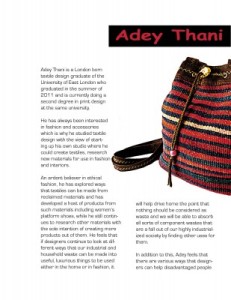

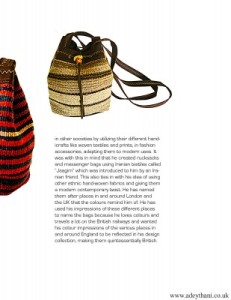

Fig 17. The publication that featured Adey Thani’s bag designs.

Figs 18-21. A magazine feature on Adey Thani and his bag designs.- Fashion Affair magazine (pages 70-73).

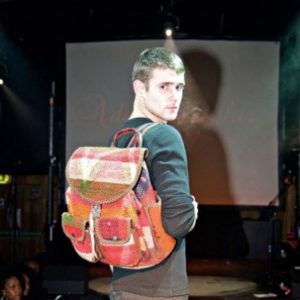

Some images from ‘Fashion meets Music’ Fashion show.

Fig 22. A model showing off one of the messenger bags by Adeysapphire Designs.

Fig 23.

Fig 24.

Fig 25.

Fig 26.

Fig 27. Some of the models doing a photo-call with me.

Fig 28. Myself walking up to take a bow. – All Photographs taken by Simon Morris photography.

Other events.

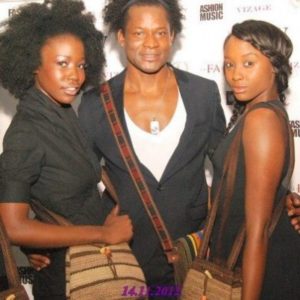

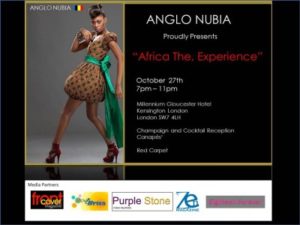

In addition to the above fashion events, I was invited to the Anglo-Nubia fashion show which showcased works by African designers who were inspired by African fabrics.

Fig 29.

I have also been invited by the organiser of the event to showcase my designs inspired by African fabrics on their website. This will serve the purpose of expanding my audience reach and give me much needed publicity.

Fig 30. From left, Benjamin Amure, Adey Thani (Designer) Gordon Flynn; PR, Fashion Affair magazine editor and Jenis Adams at the Anglo-Nubia fashion show. – Photograph by Serguei Cherkassov .

Professionally, I have been able to forge a network of fashion professionals through the use of social media, mainly twitter and facebook, attracting the attention of other social media users, some offering their services along the lines of fashion and various other supplies and I have started to build a network base of professionals that even if I don’t utilise them now, I can still do so in the future.

I have had great feedback from all of those concerned and I feel like I am ready to take things to the next level.

In addition to all of these publicity and networking, I have started to build up my customer base too. One of these is a shop owner in Camden who has been stocking my bags and requesting for more. I also took part in the Christmas fair at the University of East London, Docklands Campus, where I was able to network with other designers who participated and I was able to sell more bags as well as generated a lot of interest in my products.

Fig 31. Adeysapphire items on display at the Christmas fair in UEL.

All sorts of marketing tools have been used to attract the attention of my audience including the creation of a press release ( see below this post) which was shared through my blog on twitter and facebook. I have also subscribed to ‘AWEBER’ which is a marketing tool used to send out newsletters to subscribers of my blog and website to inform them of any new range of Adeysapphire products.

This will be utilised as soon as my new product line arrives from the factory where i am having them manufactured.

Also worth mentioning here is that labels have also been outsourced abroad where it is cheaper to make compared to here in England. My labels are made of a Damask weave using the Adeysapphire logo in red against a black background, which is consistent with the colour scheme of my website. Furthermore, I have included my digital print as a signature for all of my second batch of products which have been expanded to include wallets for gents, using Aso-Oke fabrics and Jajim, women’s bags made from my ‘nothing textiles’ and mixed with digital prints, as well as the original bags made from Jajim and digital prints. I hope to be able to expand my range even further into Shoes/slippers for men, belts and coats using the same sort of fabrics.

Fig 32. One of the gents’ wallets being made at the factory abroad.

Fig 33. One of the further additions to my bag range which will have digital prints on the inside, and Jajim on the outside.

In conclusion, I am aware that I have taken a huge calculated risk by just following my gut feeling backed up by a little research, having started with the ‘Waste to Glamour’ exhibitions (part 1 & II) and have exercised entrepreneurial spirit, filled with my passion for bags and everything ethical, which has taken me on a journey and led to me participating in fashion shows that a year ago, I really had no inkling that this would come about so soon, or being featured in a fashion magazine, but in any case, it did. My network base is growing, my product range developing, and I am going through a learning process where I am learning to use internet marketing tools to promote my work and bring my products to the notice of members of the online community. It is all paying off gradually. I have committed a little of my financial resources not knowing if I would ever get my products noticed or any of my finances back. This brings to mind the saying that ‘nothing ventured, nothing gained’. As designers, we have to take risks. Sometimes they pay off and sometimes they don’t. If they don’t pay off, then we ought to go back to the drawing board to see where we went wrong. This is still the beginning for me, and the sky seems to be the limit. It is my hope that oneday soon, rather than outsource them to manufacturers abroad, I would be having them all made in the United Kingdom.

Many thanks for reading about my Professional engagement.

– Adey Thani (designer)

Adeysapphire Design Studio.